Work Experience.

Cadet Instructor Cadre Officer

Canadian Armed Forces

Jan 2022 - Present

Nov 2025 - Present

Sept 2023 - Present

Feb 2025 - Apr 2025

Jul 2024 - Oct 2024

Aug 2023 - Aug 2023

Sept 2022 - Aug 2023

Sept 2022 - Jul 2023

Aug 2022 - Aug 2022

Jun 2022 - Aug 2022

Jan 2022 - Aug 2022

·

·

·

·

·

·

·

·

·

·

SOP / Process Development Officer - Niagara & Greater Toronto Area, 2Lt

Administration Officer, 2Lt

J3 Training Support Coordinator - Niagara & Greater Toronto Area, OCdt

J3 Training Support Coordinator - Niagara & Greater Toronto Area, OCdt

Cadet Activities Program Platoon Commander, OCdt

Standards Officer, OCdt

Assistant Supply Officer, OCdt

J35 Plans Support Staff, OCdt

Cadet Activities Program Platoon Commander, OCdt

Assistant Supply Officer, OCdt

Graduate Research Assistant / TEAching assistant

York University, Neptune Nanotechnologies Inc.

Sept 2023 - Sept 2025

EDUCATION.

Master’s of applied science (mechanical engineering)

York University (Lassonde School of Engineering)

Research in bio-based nanoparticle reinforcement of polyester adhesive nanocomposites

Sept 2023 - Sept 2025

Specialized Honours Bachelor of Engineering (mechanical)

York University (Lassonde School of Engineering)

Specializations in Aerodynamics and Composite Materials

Sept 2019 - May 2023

Projects.

DISCLAIMER: All posted materials may not be retransmitted, reproduced, rebroadcast, or otherwise distributed or used in any form without the express written consent from Nathan Hsieh.

Please feel free to browse the site. You may download material displayed on the site to any single computer only for your personal, noncommercial use, provided you also maintain all copyright and other proprietary notices. You may not, however, distribute, reproduce, republish, display, modify, transmit, reuse, repost, link to, or use any materials of the site for public or commercial purposes on any other website or otherwise without the written permission from Nathan Hsieh. Modification of any materials displayed on the site is a violation of any copyright and other proprietary rights.

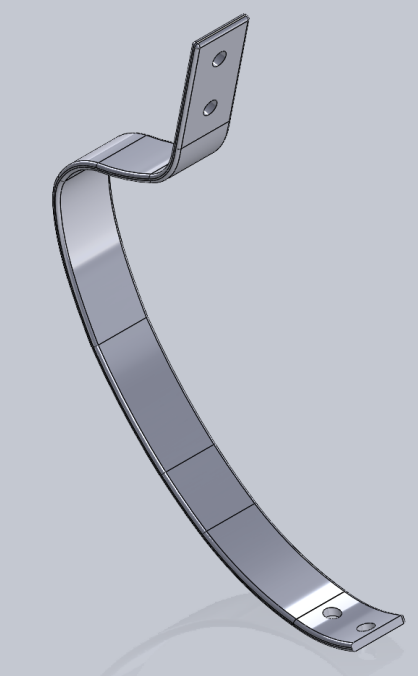

Sustainable Running Blade Prosthetic

This project aims to develop a sustainable running blade prosthetic for para-athletes. Natural fibers and bio-based resins are utilized to minimize the environmental impact of the prosthetic. The design and materials selection prioritize reducing waste and carbon footprint while ensuring easy recyclability.

Feb 2023 - Apr 2023

Lantern Design for the Canadian Coast Guard

The objective of this project is to design a modern multi-function lantern that can provide visual aid and hydrometric data to mariners. Key responsibilities in this project is to optimize the lantern's performance, develop an innovative housing, conduct high-performance material selection, and to manufacture a prototype.

Sept 2023 - Apr 2023

Aerodynamic Truck Fairing

This project aimed to create an efficient wind deflector fairing for transport trucks and trailers by minimizing fuel consumption and drag, while also reducing material use and manufacturing costs. Computational fluid dynamics simulations and finite element analysis were utilized to optimize the fairing design and identify high-stress regions.

Nov 2022 - Dec 2022

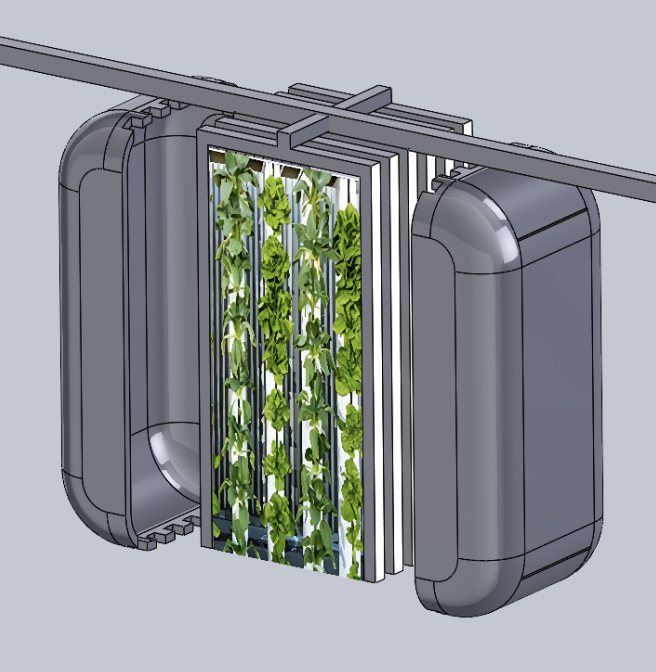

Societal Impact Design Project

This project created a modular device to promote sustainable vegetation growth in northern Ontario by reducing water consumption and energy loss on vertical farming facilities. Using a human-centered design process, 8 critical stakeholder needs were identified and addressed in the device. The final product minimized energy loss and promoted sustainable vegetation growth in the region.

Jan 2022 - Apr 2022

This project designed a finned tube double pipe heat exchanger using log mean temperature difference and effectiveness-NTU methods to maximize compactness ratio and minimize overdesign percentage. Feasible designs were analyzed and optimal designs were selected based on multiple criteria, resulting in an efficient and effective product.

Heat Exchanger Design

Mar 2022

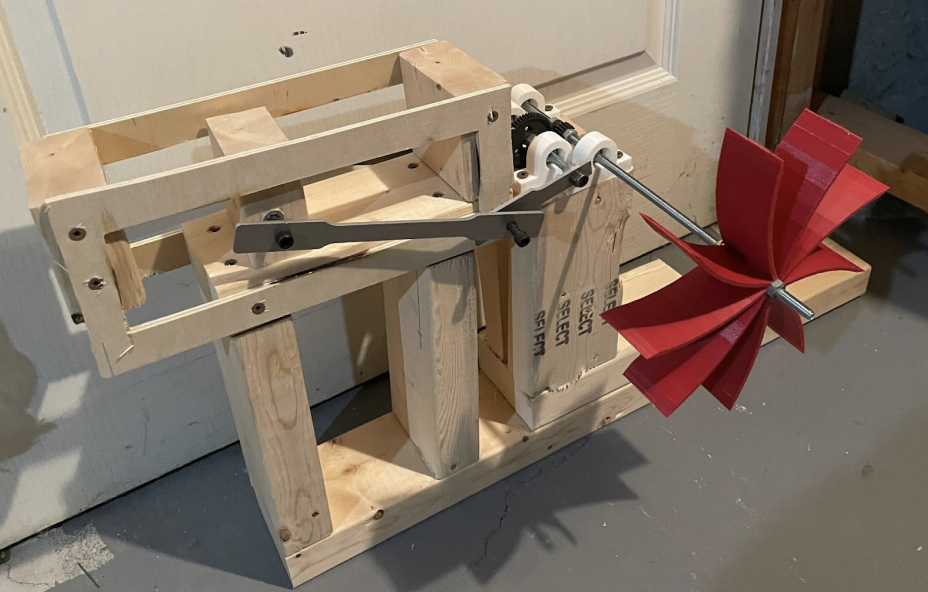

Developed a low-cost and safe can crushing mechanism powered by renewable energy to reduce the volume of emptied cans by at least 80%. The mechanism was designed with safety mechanisms to ensure user-friendliness and to prevent injuries. Cost reduction and maximizing compression were considered as secondary objectives.

CAN CRUSHER

Feb 2022 - Mar 2022

This project created a modular device to promote sustainable vegetation This project aimed to develop an electric bike design for sustainable urban transportation, reducing greenhouse gas emissions and promoting decarbonization. Through research and Solidworks iterations, the design was optimized for safety and effectiveness under loading conditions.

Electric Bike

Nov 2021 - Dec 2021

River Crossing Carrier System

Designed a rope climbing mechanism for safe passenger transport across dangerous waters in Tibet. Created executable design variations minimizing weight and eliminating cable/part failure risk. Conducted FEA analysis to optimize safety and improved efficiency by 75% with zero injury risk.

Nov 2021 - Dec 2021

Density Measurement System

Developed a density measurement system for homogeneous fluid mixtures using a custom MIMO setup and LabView/Arduino programming. Implemented 5 sensors and 30 components to produce accurate readings within tolerances, exploring load cell signal conditioning, data acquisition, and analysis.

Nov 2021 - Dec 2021

PRESentations & Publications.

Processing Strategies for High Performance Polyester-Based Adhesives Reinforced by Bio-derived Nanoparticles

Journal of Manufacturing and Materials Processing

Nov 2025

This study explores the enhancement of mechanical and adhesive properties of polyester (PE) resins through the incorporation of bio-derived chitin nanowhiskers (CNWs) into the polymer matrix. CNWs are high-performance nanoparticles extracted from chitin, an abundant and renewable biopolymer. The research investigates the effects of processing strategies and CNW loadings on the chemical structure, thermal behavior, mechanical strength, and adhesive performance of PE–CNW nanocomposites. CNWs were incorporated into the PE matrix via slurry compounding using different suspension media (ethanol, acetone, and methyl ethyl ketone) and through direct mechanical mixing with CNW dry powders. Experimental results show that the thermal and mechanical properties of the nanocomposites are highly sensitive to both the thermal history during processing and the choice of suspension medium. Most importantly, the optimal adhesive performance was achieved via slurry compounding with a CNW suspension in ethanol, following an evaporative pre-treatment of the suspension to reduce ethanol content and thereby minimize transesterification of the polyester matrix.

Design and fabrication of green polyester-based adhesives reinforced by bio-based nanoparticles

May 2025

The Canadian Society for Mechanical Engineering (CSME) 2025 Conference

DOI: https://doi.org/10.82417/mghw-9395

SPE Thermoset 2025 Conference

(presented by CEO Aaron Guan, Neptune Nanotechnologies Inc.)

AWARDS.

York University

Mechanical Engineering Excellence Award for Graduate Research

Aug 2025

The Duke of Edinburgh International Award

Duke of Edinburgh’s International Award, Gold Distinction

Duke of Edinburgh’s International Award, Silver Distinction

Feb 2023

Apr 2018

Canadian Armed Forces

Cadet Instructor Cadre Citizen Scholarship

Dec 2023

Government of Canada

COVID-19 Humanitarian Service Medal

June 2022

883 Air Commodore Leonard Birchall Royal Canadian Air Cadet Squadron

Commanding Officer’s Commendation

Lord Strathcona Medal (LSM)

3D (Drill, Dress, and Deportment) Award

Canada Fitness: Excellence Qualification

Air Cadet League Service Medal

883 Air Commodore Leonard Birchall Squadron Leadership Award

Dec 2022

June 2022

June 2022

June 2022

Dec 2018

June 2017